Welding Terms Glossary

Abrasive – Slag used for cleaning or surface roughening.

Active Flux – Submerged-arc welding flux from which the amount of elements deposited in the weld metal is dependent upon welding conditions, primarily arc voltage.

Adhesive Bonding – Surfaces, solidifies to produce an adhesive bond.

Air Carbon Arc Cutting – An arc cutting process in which metals to be cut are melted by the heat of carbon arc and the molten metal is removed by a blast of air.

All-Weld-Metal Test Specimen – A test specimen with the reduction section composed wholly of weld metal.

Alloying – Adding a metal or alloy to another metal or alloy.

Alternating Current (AC) – Electric current that reverses direction periodically, usually many times per second.

Annealed Condition – A metal or alloy that has been heated and then cooled to remove internal stresses and to make the material less brittle.

Arc Blow – The deflection of an electric arc from its normal path because of magnetic forces.

Arc Cutting – A group of thermal cutting processes that severs or removes metal by melting with the heat of an arc between an electrode and the work piece.

Arc Force – The axial force developed by an arc plasma.

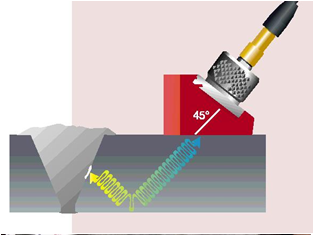

Arc Gouging – An arc cutting procedure used to form a bevel or groove.

Arc Length – The distance from the tip of the electrode or wire to the work piece.

Arc Time – The time during which an arc is maintained.

Arc Voltage – The voltage across the welding arc.

Arc Welding – A group of welding processes which produces coalescence of metals by heating them with an arc, with or without the application of pressure and with or without the use of filler metal.

Arc Welding Deposition Efficiency (%) – The ratio of the weight of filler metal deposited to the weight of filler metal melted.

Arc Welding Electrode – A part of the welding system through which current is conducted that ends at the arc.

As-Welded – The condition of the weld metal, after completion of welding, and prior to any subsequent thermal or mechanical treatment.

Atomic Hydrogen Welding – An arc welding process which produces coalescence of metals by heating them with an electric arc maintained between two metal electrodes in an atmosphere of hydrogen.

Austenitic – Composed mainly of gamma iron with carbon in solution.

Autogenous Weld – A fusion weld made without the addition of filler metal.

Automatic – The control of a process with equipment that requires little or no observation of the welding and no manual adjustment of the equipment controls.

Back Gouging – The removal of weld metal and base metal from the other side of a partially welded joint to assure complete penetration upon subsequent welding from that side.

Backfire – The momentary recession of the flame into the welding or cutting tip followed by reappearance or complete extinction of the flame.

Backhand Welding – A welding technique where the welding torch or gun is directed opposite to the direction of welding.

Backing – A material (base metal, weld metal, or granular material) placed at the root of a weld joint for the purpose of supporting molten weld metal.

Backing Gas – A shielding gas used on the underside of a weld bead to protect it from atmospheric contamination.

Backing Ring – Backing in the form of a ring, generally used in the welding of pipe.

Back-Step Sequence – A longitudinal sequence in which the weld bead increments are deposited in the direction opposite to the progress of welding the joint.

Base Metal (material) – The metal (material) to be welded, brazed, soldered, or cut. See also substrate.

Bend Radius – Radius of curvature on a bend specimen or bent area of a formed part. Measured on the inside of a bend.

Bevel – An angled edge preparation.

Blanking – Process of cutting material to size for more manageable processing.

Braze Welding – A method of welding by using a filler metal, having a liquidus above 840 °F (450 °C) and below the solidus of the base metals.

Brazing – A group of welding processes which produces coalescence of materials by heating them to a suitable temperature and by using a filler metal, having a liquidus above 840 °F (450 °C) and below the solidus of the base materials. The filler metal is distributed between the closely fitted surfaces of the joint by capillary attraction.

Burr – A rough ridge, edge, protuberance, or area left on metal after cutting, drilling, punching, or stamping.

Buttering – A form of surfacing in which one or more layers of weld metal are deposited (for example, a high alloy weld deposit on steel base metal which is to be welded to a dissimilar base metal). The buttering provides a suitable transition weld deposit for subsequent completion of the butt weld on the groove face of one member.

Butt Joint – A joint between two members lying in the same plane.

Camber – Deviation from edge straightness, usually the greatest deviation of side edge from a straight line.

Cap Pass – The final pass of a weld joint.

Carrier Gas – In thermal spraying, the gas used to carry powdered materials from the powder feeder or hopper to the gun.

Capillary Action – The action by which the liquid surface is elevated or depressed where it contacts a solid because the liquid molecules are attracted to one another and to the solid molecules.

Cladding – A thin (> 0.04″) layer of material applied to the base material to improve corrosion or wear resistance of the part.

Clad Metal – A composite metal containing two or three layers that have been welded together. The welding may have been accomplished by roll welding, arc welding, casting, heavy chemical deposition, or heavy electroplating.

Coalescence – The uniting of many materials into one body.

Coherent – Moving in unison.

Cold Lap – Incomplete fusion or overlap.

Collimate – To render parallels to a certain line or direction.

Complete Fusion – Fusion that has occurred over the entire base material surfaces intended for welding, and between all layer and passes.

Complete Joint Penetration – Joint penetration in which the weld metal completely fills the groove and is fused to the base metal throughout its total thickness.

Constant Current Power Source – An arc welding power source with a volt-ampere output characteristic that produces a small welding current change from a large arc voltage change.

Constant Voltage Power Source – An arc welding power source with a volt-ampere output characteristic that produces a large welding current change from a small arc voltage change.

Contact Tube – A system component that transfers current from the torch gun to a continuous electrode.

Contact Resistance – The resistance in ohms between the contacts of a relay, switch, or other device when the contacts are touching each other.

Contact Tube – A device which transfers current to a continuous electrode

Covered Electrode – A filler metal electrode used in shielded metal-arc welding, consisting of a metal-wire core with a flux covering.

Crater – In arc welding, a depression on the surface of a weld bead.

Crater Crack – A crack in the crater of a weld bead.

Cryogenic – Refers to low temperatures, usually -200 o (-130 o) or below.

Cutting Attachment – A device for converting an oxy-fuel gas-welding torch into an oxy-fuel cutting torch.

Cylinder – A portable container used for transportation and storage of a compressed gas.

Defect – A discontinuity or discontinuities that by nature or accumulated effect (for example, total crack length) renders a part or product unable to meet minimum applicable acceptance standards or specifications.

Density – The ratio of the weight of a substance per unit volume; e.g. mass of a solid, liquid, or gas per unit volume at a specific temperature.

Deposited Metal – Filler metal that has been added during welding, brazing or soldering.

Deposition Efficiency – In arc welding, the ratio of the weight of deposited metal to the net weight of filler metal consumed, exclusive of stubs.

Deposition Rate – The weight of material deposited in a unit of time. It is usually expressed as pounds/hour (lb/h) or kilograms per hour (kg/h).

Depth of Fusion – The distance that fusion extends into the base metal or previous pass from the surface melted during welding.

Dew Point – The temperature and pressure at which the liquefaction of a vapor begins. Usually applied to condensation of moisture from the water vapor in the atmosphere.

Dilution – The change in chemical composition of a welding filler material caused by the admixture of the base material or previously deposited weld material in the deposited weld bead. It is normally measured by the percentage of base material or previously deposited weld material in the weld bead.

Direct Current – Electric current that flows in one direction.

Direct Current Electrode Negative (DCEN) – The arrangement of direct current arc welding leads in where the electrode is the negative pole and work-piece is the positive pole of the welding arc.

Direct Current Electrode Positive (DCEP) – The arrangement of direct current arc welding leads in where the electrode is the positive pole and work-piece is the negative pole of the welding arc.

Duty Cycle – The percentage of time during a time period that a power source can be operated at rated output without overheating.

Dynamic Load – A force exerted by a moving body on a resistance member, usually in a relatively short time interval.

Electrode Extension – The length of electrode extending beyond the end of the contact tube.

Electrode Holder – A welding process that produces coalescence of metals with the heat obtained from a concentrated beam composed primarily of high velocity electrons

Electron Beam Welding – A welding process producing coalescence of metals with molten slag which melts the filler metal and the surfaces of the work to be welded. The molten weld pool is shielded by the slag, which moves along the full cross section of the joint as welding progresses.

Electroslag Welding – A welding process producing coalescence of metals with molten slag which melts the filler metal and the surfaces of the work to be welded. The molten weld pool is shielded by the slag, which moves along the full cross section of the joint as welding progresses.

Eutectoid Composition – A mixture of phases whose composition are determined by the eutectoid point in the solid region of an equilibrium diagram and whose constituents are formed by eutectoid reaction.

Facing Surface – The surfaces of materials in contact with each other and joined or about to be joined together.

Filler Material – The material to be added in making a welded, brazed, or soldered joint.

Fillet Weld – A weld of approximately triangular cross section that joins two surfaces approximately at right angles to each other in a lap joint, T-joint, or corner joint.

Filter Plate – A transparent plate tinted in varying darkness for use in goggles, helmets and hand shields to protect workers from harmful ultraviolet, infrared and visible radiation.

Flame Spraying – A thermal spraying process using an oxy-fuel gas flame as the source of heat for melting the coating material.

Flammable Range – The range over which a gas at normal temperature (NTP) forms a flammable mixture with air.

Flat Welding Position – A welding position where the weld axis is approximately horizontal and the weld face lies in an approximately horizontal plane.

Flashback – A recession of the flame into or back of the mixing chamber of the torch.

Flashback Arrestor – A device to limit damage from a flashback by preventing the propagation of the flame front beyond the point at which the arrestor is installed.

Flashing – The violent expulsion of small metal particles due to arcing during flash butt welding.

Flux – Material used to prevent, dissolve, or facilitate removal of oxides and other undesirable surface substances.

Flux Cored Arc Welding (FCAW) – An arc welding process that produces coalescence of metals by means of tubular electrode. Shielding gas may or may not be used.

Friction Welding – A solid welding process which produces coalescence of material by the heat obtained from a mechanically induced sliding motion between rubbing surfaces. The work parts are held together under pressure.

Friction Stir Welding – A solid-state welding process, which produces coalescence of material by the heat obtained from a mechanically induced rotating motion between tightly butted surfaces. The work parts are held together under pressure.

Forehand Welding – A welding technique where the welding torches or gun is pointed toward the direction of welding.

Fusion – The melting together of filler metal and base metal (substrate), or of base metal only, which results in coalescence.

Gas Metal Arc Welding (GMAW) – An arc welding process where the arc is between a continuous filler metal electrode and the weld pool. Shielding from an externally supplied gas source is required.

Gas Tungsten Arc Welding (GTAW) – An arc welding process where the arc is between a tungsten electrode (non-consumable) and the weld pool. The process is used with an externally supplied shielding gas.

Gas Welding – Welding with the heat from an oxy-fuel flame, with or without the addition of filler metal or pressure.

Globular-Spray Transition Current – In GMAW/Spray Transfer, the value at which the electrode metal transfer changes from globular to spray mode as welding current increases for any given electrode diameter.

Globular Transfer – In arc welding, a type of metal transfer in which molten filler metal is transferred across the arc in large droplets.

Groove Weld – A weld made in a groove between two members. Examples: single V, single U, single J, double bevel etc.

Hard-Facing – Surfacing applied to a workplace to reduce wear.

Heat-Affected Zone – That section of the base metal, generally adjacent to the weld zone, whose mechanical properties or microstructure, have been altered by the heat of welding.

Hermetically Sealed – Airtight. Heterogenous – A mixture of phases such as: liquid-vapor or solid-liquid-vapor.

Hot Crack – A crack formed at temperatures near the completion of weld solidification.

Hot Pass – In pipe welding, the second pass which goes over the root pass.

Inclined Position – In pipe welding, the pipe axis angles 45 degrees to the horizontal position and remains stationary.

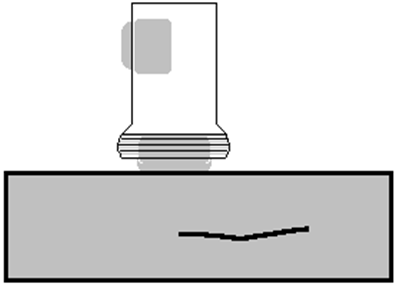

Incomplete Fusion – A weld discontinuity where fusion did not occur between weld metal and the joint or adjoining weld beads.

Incomplete Joint Penetration – A condition in a groove weld where weld metal does not extend through the joint thickness.

Inert Gas – A gas that normally does not combine chemically with the base metal or filler metal.

Intergranular Penetration – The penetration of filler metal along the grain boundaries of a base metal.

Interpass Temperature – In a multi-pass weld, the temperature of the weld area between passes.

Ionization Potential – The voltage required to ionize (add or remove an electron) a material.

Joint – The junction of members or the edges of members that are to be joined or have been joined.

Kerf – The width of the cut produced during a cutting process.

Keyhole – A technique of welding in which a concentrated heat source penetrates completely through a work-piece forming a hole at the leading edge of the molten weld metal. As the heat source progresses, the molten metal fills in behind the hole to form the weld bead.

Lap Joint – A joint between two overlapping members in parallel planes.

Laser – A device that provides a concentrated coherent light beam. Laser is an acronym for Light Amplification by Stimulated Emission of Radiation.

Laser Beam Cutting – A process that severs material with the heat from a concentrated coherent beam impinging upon the work-piece.

Laser Beam Welding – A process that fuses material with the heat from a concentrated coherent beam impinging upon the members to be joined.

Leg of Fillet Weld – The distance from the root of the joint to the toe of the fillet weld.

Liquidus – The lowest temperature at which a metal or an alloy is completely liquid.

Mandrel – A metal bar serving as a core around which other metals are cast, forged, or extruded, forming a true, center hole.

Manifold – A multiple header for interconnection of gas or fluid sources with distribution points.

Martensitic – An interstitial, super-saturated solid solution of carbon in iron, having a body-centered tetragonal lattice.

Manual Welding – A welding process where the torch or electrode holder is manipulated by hand. MIG – See Gas Metal Arc Welding (GMAW).

Mechanical Bond – The adherence of a thermal-spray deposit to a roughened surface by particle interlocking.

Mechanized Welding – Welding with equipment where manual adjustment of controls is required in response to variations in the welding process. The torch or electrode holder is held by a mechanical device.

Melting Range – The temperature range between solidus and liquidus.

Melt-Through – Visible reinforcement produced on the opposite side of a welded joint from one side.

Metal Cored Arc Welding – A tubular electrode process where the hollow configuration contains alloying materials.

Metal Cored Electrode – A composite tubular electrode consisting of a metal sheath and a core of various powdered materials, producing no more than slag islands on the face of the weld bead. External shielding is required.

Molecular Weight – The sum of the atomic weights of all the constituent atoms in the molecule of an element or compound.

Monochromatic – The color of a surface that radiates light, containing an extremely small range of wavelengths.

Neutral Flame – An oxy-fuel gas flame that is neither oxidizing nor reducing.

Open-Circuit Voltage – The voltage between the output terminals of the welding machine when no current is flowing in the welding circuit.

Orifice Gas – In plasma arc welding and cutting, the gas that is directed into the torch to surround the electrode. It becomes ionized in the arc to form the plasma and issues from the orifice in the torch nozzle as the plasma jet.

Oxidizing Flame – An oxy-fuel gas flame having an oxidizing effect (excess oxygen).

Peening – The mechanical working of metals using impact blows.

Pilot Arc – A low current continuous arc between the electrode and the constricting nozzle of a plasma torch that ionizes the gas and facilitates the start of the welding arc.

Plasma – A gas that has been heated to at least partially ionized condition, enabling it to conduct an electric current.

Plasma Arc Cutting (PAC) – An arc cutting process using a constricted arc to remove the molten metal with a high-velocity jet of ionized gas from the constricting orifice.

Plasma Arc Welding (PAW) – An arc welding process that uses a constricted arc between a non-consumable electrode and the weld pool (transferred arc) or between the electrode and the constricting nozzle (non-transferred arc). Shielding is obtained from the ionized gas issuing from the torch.

Plasma Spraying (PSP) – A thermal spraying process in which a non-transferred arc is used to create an arc plasma for melting and propelling the surfacing material to the substrate.

Plug Weld – A circular weld made through a hole in one member of a lap or T joint.

Porosity – A hole-like discontinuity formed by gas entrapment during solidification.

Post-Heating – The application of heat to an assembly after welding, brazing, soldering, thermal spraying, or cutting operation.

Postweld Heat Treatment – Any heat treatment subsequent to welding.

Preform – The initial press of a powder metal that forms a compact.

Preheating – The application of heat to the base metal immediately before welding, brazing, soldering, thermal spraying, or cutting.

Preheat Temperature – The temperature of the base metal immediately before welding is started.

Procedure Qualification – Demonstration that a fabricating process, such as welding, made by a specific procedure can meet given standards.

Pull Gun Technique – Same as backhand welding.

Pulsed Power Welding – Any arc welding method in which the power is cyclically programmed to pulse so that the effective but short duration values of a parameter can be utilized. Such short duration values are significantly different from the average value of the parameter. Equivalent terms are pulsed voltage or pulsed current welding.

Pulsed Spray Welding – An arc welding process variation in which the current is pulsed to achieve spray metal transfer at average currents equal to or

less than the globular to spray transition current.

Push Angle – The travel angle where the electrode is pointing in the direction of travel.

Rake Angle – Slope of a shear knife from end to end.

Reducing Flame – A gas flame that has a reducing effect, due to the presence of excess fuel.

Reinforcement – Weld metal, at the face or root, in excess of the metal necessary to fill the joint.

Residual Stress – Stress remaining in a structure or member, as a result of thermal and/or mechanical treatment. Stress arises in fusion welding primarily because the melted material contracts on cooling from the solidus to room temperature.

Reverse Polarity – The arrangement of direct current arc welding leads with the work as the negative pole and the electrode as the positive pole of the welding arc.

Root Opening – A separation at the joint root between the work pieces.

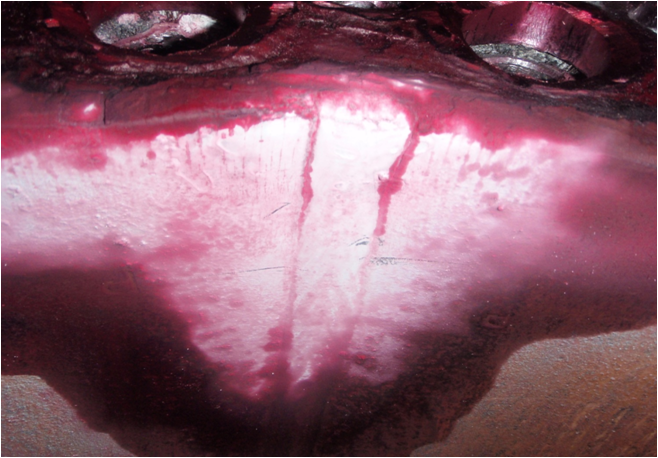

Root Crack – A crack at the root of a weld.

Self-Shielded Flux Cored Arc Welding (FCAW-S) – A flux-cored arc welding process variation in which shielding gas is obtained exclusively from the flux within the electrode.

Shielded Metal Arc Welding (SMAW) – A process that welds by heat from an electric arc, between a flux-covered metal electrode and the work. Shielding comes from the decomposition of the electrode covering.

Shielding Gas – Protective gas used to prevent atmospheric contamination.

Soldering – A joining process using a filler metal with a liquidus less than 840 °F and below the solidus of the base metal.

Solid State Welding – A group of welding processes which produces coalescence at temperatures essentially below the melting point of the base materials being joined, without the addition of a brazing filler metal. Pressure may of may not be used.

Solidus – The highest temperature at which a metal or alloy is completely solid.

Spatter – Metal particles expelled during welding that do not form a part of the weld.

Spray Transfer – In arc welding, a type of metal transfer in which molten filler metal is propelled axially across the arc in small droplets.

Standard Temperature and Pressure (STP) – An internationally accepted reference base where standard temperature is 0 °C (32 °f) and standard pressure is one atmosphere, or 14.6960 psia.

Stick-Out – The length of unmelted electrode extending beyond the end of the contact tube in continuous welding processes.

Straight Polarity – Direct current arc welding where the work is the positive pole.

Stress Relief Heat Treatment – Uniform heating of a welded component to a temperature sufficient to relieve a major portion of the residual stresses.

Stress Relief Cracking – Cracking in the weld metal or heat affected zone during post-weld heat treatment or high temperature service.

Stringer Bead – A weld bead made without transverse movement of the welding arc.

Submerged Arc Welding – A process that welds with the heat produced by an electric arc between a bare metal electrode and the work. A blanket of granular fusible flux shields the arc.

Substrate – Any material upon which a thermal-spray deposit is applied.

Synergistic – An action where the total effect of two active components in a mixture is greater than the sum of their individual effects.

Tack Weld – A weld made to hold parts of a weldment in proper alignment until the final welds are made.

Tenacious – Cohesive, tough.

Tensile Strength – The maximum stress a material subjected to a stretching load can withstand without tearing.

Thermal Conductivity – The quantity of heat passing through a material.

Thermal Spraying – A group of processes in which finely divided metallic or non-metallic materials are deposited in a molten or semimolten condition to form a coating.

Thermal Stresses – Stresses in metal resulting from non-uniform temperature distributions.

Thermionic – The emission of electrons as a result of heat.

Throat – In welding, the area between the arms of a resistance welder. In a press, the distance from the slide centerline to the frame, of a gap-frame press.

TIG Welding – See Gas Tungsten Arc Welding (GTAW).

Torch Standoff Distance – The dimension from the outer face of the torch nozzle to the work piece.

Transferred Arc – In plasma arc welding, a plasma arc established between the electrode and the work-piece.

Underbead Crack – A crack in the heat-affected zone generally not extending to the surface of the base metal.

Undercut – A groove melted into the base plate adjacent to the weld toe or weld root and left unfilled by weld metal.

Vapor Pressure – The pressure exerted by a vapor when a state of equilibrium has been reached between a liquid, solid or solution and its vapor. When the vapor pressure of a liquid exceeds that of the confining atmosphere, the liquid is commonly said to be boiling.

Viscosity – The resistance offered by a fluid (liquid or gas) to flow.

Weldability – The capacity of a material to be welded under the fabrication conditions imposed into a specific, suitably designed structure and to perform satisfactorily in the intended service.

Weld Bead – The metal deposited in the joint by the process and filler wire used.

Welding Leads – The work piece lead and electrode lead of an arc welding circuit.

Welding Wire – A form of welding filler metal, normally packaged as coils or spools, that may or may not conduct electrical current depending upon the welding process used.

Weld Metal – The portion of a fusion weld that has been completely melted during welding.

Weld Pass – A single progression of welding along a joint. The result of a pass is a weld bead or layer.

Weld Pool – The localized volume of molten metal in a weld prior to its solidification as weld metal.

Weld Puddle – A non-standard term for weld pool.

Weld Reinforcement – Weld metal in excess of the quantity required to fill a joint.

Welding Sequence – The order in which weld beads are deposited in a weldment.

Wetting – The phenomenon whereby a liquid filler metal or flux spreads and adheres in a thin continuous layer on a solid base metal.

Wire Feed Speed – The rate at which wire is consumed in welding.

Work Lead – The electric conductor between the source of arc welding current and the work.