RBI Risk Based Inspection

Chapter 3

Basic Concepts

What is Risk?

- Risk is something that we live with on a day-to-day basis

- What is a Risk Decision?

- Examples from every day life

An Example of a Risky Decision

Acceptance of Risk

- We accept risk because the probability of a serious catastrophe is sufficiently low to make it acceptable

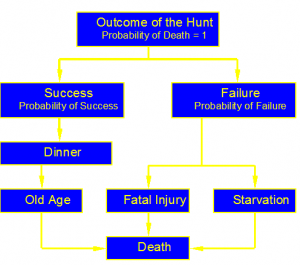

Risk

- Risk is the combination of the probability of an event occurring during some time period and the consequence (generally negative) associated with the event

Risk = Probability x Consequence

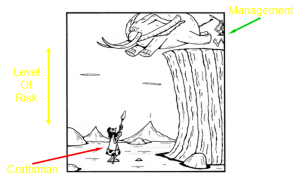

Perception of Risk Versus Reality

Management Perception

Engineers

Supervisors

Operators

Craftsman Reality

A Perception of a Risky Decision

Risk Management and Risk Reduction

Risk Management and Risk Reduction

- Not really synonymous

- Risk reduction is a part of risk management

- Act of mitigating a known risk to a lower level

- Risk Management is a process

- To assess risk

- To determine if risk reduction is required

- To develop a plan to maintain risks at an acceptable level

- Some risks may be identified as acceptable

- Some risks may be inherent

Management of Risk Using RBI

Evolution of Inspection Intervals

Evolution of Inspection Intervals

- Inspection programs are established to detect and evaluate deterioration due to in-service operations

- Periodic verification of equipment integrity evolved as “calendar-based” intervals

- Effectiveness varied widely

Evolution of Inspection Approach

- Better understanding of type and rate of deterioration

- Intervals became more dependent on equipment condition

- Codes and standards evolved

- Percentage of equipment life interval

- On-stream in lieu of internal inspection

- Process environment induced cracking

- Consequence based inspection intervals

Traditional Equipment Inspection

- Ultimate Goal of Inspection

- Safety and Reliability of Operating Facilities

- RBI Approach

- Focuses attention specifically on equipment and associated deterioration mechanisms representing the most risk to the facility

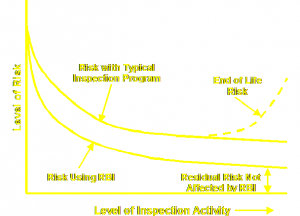

Inspection Optimization

- Optimization for planning and implementing a risk based inspection program needs information on:

- Risk associated with equipment

- Relative effectiveness of inspection techniques to reduce risk

- Not all inspection programs are equally effective in detecting in-service deterioration and reducing risks

- Various inspection techniques are usually available to detect any given deterioration mechanism

- Each method will have a different effectiveness.

Relative Risk vs. Absolute Risk

- Complexity of risk calculation is function of factors affecting risk

- Absolute risk is virtually impossible to determine because of too many uncertainties

- RBI is focused on a systematic determination of relative risk

- Risk acceptance may be evaluated by sensitivity analysis