MT MAGNETIC PARTICLE TESTING

MAGNETIC PARTICLE TESTING MT:

MT is based on the principle of magnetisation of materials.

STEPS INVOLVED IN MAGNETIC PARTICLE TESTING MT:

- Pre clean the surface.

- Demagnetize the object.

- Clean the surface.

- Inspect visually for any gross irregularity.

- Magnetise the object.

- Apply the magnetic particles.

- Observe for indications and mark them..

- Record the observations.

- Clean and de-magnetize the object.

- Apply protective coating.

CLEAN THE SURFACE:

MAGNETIZM:

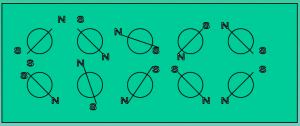

Random Orientation Of Molecules

in an Un-magnetized Specimen

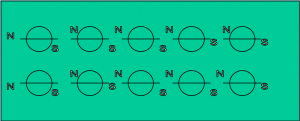

Magnetically Aligned Molecules

in a Magnetized Specimen

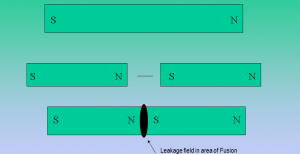

Cut-and-Fused Bar Magnet Illustrating Opposite Polarity

DOMAIN:

A saturated macroscopic structure in ferromagnetic materials where the elementary particles (electron spins) are aligned in one direction by inter atomic forces. A domain would be a saturated permanent magnet.

RETENTIVITY:

- The capacity of a substance to retain magnetism after the magnetizing force is reduced to zero.

COERCIVE FORCE:

- The magnetizing field strength required to bring the magnetic flux density of a magnetized material to zero.

LONGITUDINAL MAGNETIZATION:

- Magnetization in which the flux lines traverse the component in a direction essentially parallel to its longitudinal axis.

CIRCULAR MAGNETIZATION:

- The magnetization in an object resulting from current passed longitudinally through the object itself or through an inserted central conductor.

CURRENT FOR MAGNETIZATION:

- AC.

- DC.

- HWDC.

APPLICATION OF MAGNETIC PARTICLE TESTING MT:

- Can be applied for detection of both surface and sub-surface discontinuities.

- Cost of testing MT is comparatively lower than other methods.

- Required level of operator skill is not high .

- Portable and Stationery equipments are available.

- MT have permanent records of the indications.

- Interpretation of indications is not difficult .

LIMITATIONS OF MAGNETIC PARTICLE TESTING MT:

- Volumetric discontinuities cannot be detected. Depth of detection is up to 6mm only.

- Can be applied only on ferromagnetic materials

- Possibility of local overheating and burning exist.