RADIOGRAPHY OR RADIOGRAPHIC TESTING

- This module presents information on the NDT method of radiographic inspection or radiography.

- Radiography uses penetrating radiation that is directed towards a component.

- The component stops some of the radiation. The amount that is stopped or absorbed is affected by material density and thickness differences.

- These differences in “absorption” can be recorded on film, or electronically.

Outline

- Electromagnetic Radiation

- General Principles of Radiography

- Sources of Radiation

–Gamma Radiography

–X-ray Radiography

- Imaging Modalities

- Advantages and Limitations

- Glossary of Terms

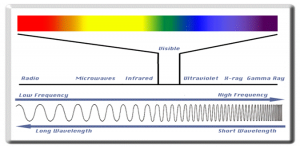

Electromagnetic Radiation

The radiation used in Radiography testing is a higher energy (shorter wavelength) version of the electromagnetic waves that we see every day. Visible light is in the same family as x-rays and gamma rays.

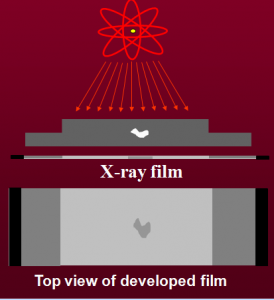

General Principles of Radiography

General Principles of Radiography

The part is placed between the radiation source and a piece of film. The part will stop some of the radiation. Thicker and more dense area will stop more of the radiation.

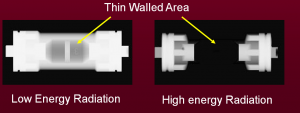

The film darkness (density) will vary with the amount of radiation reaching the film through the test object. The energy of the radiation affects its penetrating power. Higher energy radiation can penetrate thicker and more dense materials.

The energy of the radiation affects its penetrating power. Higher energy radiation can penetrate thicker and more dense materials.

The radiation energy and/or exposure time must be controlled to properly image the region of interest.

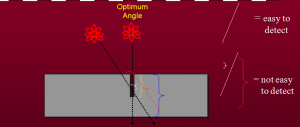

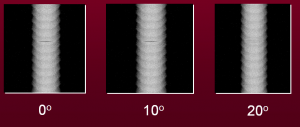

Radiography has sensitivity limitations when detecting cracks.

X-rays “see” a crack as a thickness variation and the larger the variation, the easier the crack is to detect.

When the path of the x-rays is not parallel to a crack, the thickness variation is less and the crack may not be visible.

Since the angle between the radiation beam and a crack or other linear defect is so critical, the orientation of defect must be well known if radiography is going to be used to perform the inspection.

Two of the most commonly used sources of radiation in industrial radiography are x-ray generators and gamma ray sources. Industrial radiography is often subdivided into “X-ray Radiography” or “Gamma Radiography”, depending on the source of radiation used.

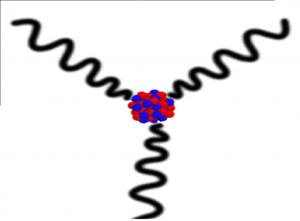

- Gamma rays are produced by a radioisotope.

- A radioisotope has an unstable nuclei that does not have enough binding energy to hold the nucleus together.

- The spontaneous breakdown of an atomic nucleus resulting in the release of energy and matter is known as radioactive decay.

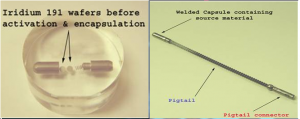

Most of the radioactive material used in industrial radiography is artificially produced.

Most of the radioactive material used in industrial radiography is artificially produced.

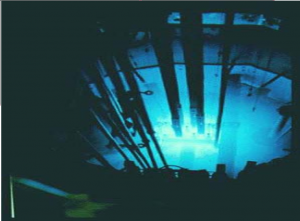

This is done by subjecting stable material to a source of neutrons in a special nuclear reactor.This process is called activation.

Unlike X-rays, which are produced by a machine, gamma rays cannot be turned off. Radioisotopes used for gamma radiography are encapsulated to prevent leakage of the material.The radioactive “capsule” is attached to a cable to form what is often called a “pigtail.”

Unlike X-rays, which are produced by a machine, gamma rays cannot be turned off. Radioisotopes used for gamma radiography are encapsulated to prevent leakage of the material.The radioactive “capsule” is attached to a cable to form what is often called a “pigtail.”

Unlike gamma rays, x-rays are produced by an X-ray generator system. These systems typically include an X-ray tube head, a high voltage generator, and a control console.

X-rays are produced by establishing a very high voltage between two electrodes, called the anode and cathode.

X-rays are produced by establishing a very high voltage between two electrodes, called the anode and cathode.

To prevent arcing, the anode and cathode are located inside a vacuum tube, which is protected by a metal housing

Imaging Modules:

Several different imaging methods are available to display the final image in industrial radiography:

- Film Radiography

- Real Time Radiography

- Computed Tomography (CT)

- Digital Radiography (DR)

- Computed Radiography (CR)

Advantages of Radiography

- Technique is not limited by material type or density.

- Can inspect assembled components.

- Minimum surface preparation required.

- Sensitive to changes in thickness, corrosion, voids, cracks, and material density changes.

- Detects both surface and subsurface defects.

- Provides a permanent record of the inspection.

Disadvantages of Radiography

- Many safety precautions for the use of high intensity radiation.

- Many hours of technician training prior to use.

- Access to both sides of sample required.

- Orientation of equipment and flaw can be critical.

- Determining flaw depth is impossible without additional angled exposures.

- Expensive initial equipment cost.

Glossary of Terms

- Activation: the process of creating radioactive material from stable material usually by bombarding a stable material with a large number of free neutrons. This process typically takes place in a special nuclear reactor.

- Anode: a positively charged electrode.

- Automatic Film Processor: a machine designed to develop film with very little human intervention. Automatic processors are very fast compared to manual development

- Capacitor: an electrical device that stores an electrical charge which can be released on demand

- Cathode: a negatively charged electrode.

- Darkroom: a darkened room for the purpose of film development. Film is very sensitive to exposure by visible light and may be ruined.

- Exposure: the process of radiation penetrating and object.

- Gamma Rays: electromagnetic radiation emitted from the nucleus of a some radioactive materials

To Learn Radiography or Radiographic Testing : Contact Ph: +91 – 85261 41878 Email ID: esl@esltraining.in.