NON DESTRUCTIVE TESTING NDT

NOTE: CONTINUITY OF PREVIOUS ARTICLE…

Removability

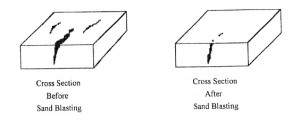

High adhesion between the penetrant and the material of the test specimen will result in the penetrant being very difficult to remove from the test surface. Capillary action also becomes a problem on very rough or porous surfaces. The minute valleys and openings on the test surface tend to hold the penetrant on the surface making the excess penetrant difficult to remove. When the excess penetrant can not be adequately removed, the developer coating will become saturated with penetrant and interpretation of small indications becomes impossible due to a heavy background.

Viscosity

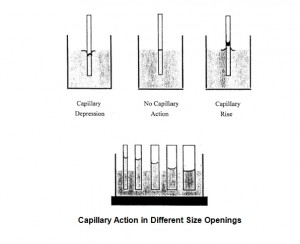

The capillary action of the penetrant and the speed of penetration into the discontinuity openings is controlled by the viscosity of the penetrant. Viscosity is defined as a liquids resistance to flow and is measured in Centistokes ( Cs ). Viscosity is directly affected by the temperature of the test surface. The higher the temperature of the penetrant, the lower the viscosity. The penetrants viscosity will breakdown and cause the penetrant to have a thinner consistency. The lower the viscosity of a penetrant, the thinner the liquid and the faster it will penetrate an opening. The opposite is also true. Lower temperatures of the penetrant will increase viscosity and thicken the consistency of the penetrant causing it to gel and become sluggish. Penetration speed will ultimately decrease. PT is temperature limited because of the effects of temperature on viscosity.

Simply stated, an ideal penetrant will have a low Surface Tension, low Contact Angle, low Viscosity, and good Wetability. There is no one single property that makes a good penetrant.

NON DESTRUCTIVE TESTING

LIQUID PENETRANT CATEGORIES

TYPE OF DYE contained in the penetrant :

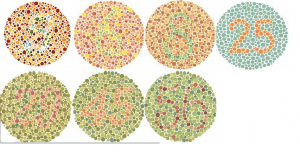

- FLUORESCENT – penetrants contain a green dye which fluoresces under ultraviolet light. This type of penetrant is considered the most sensitive. Fluorescent penetrants are considered more sensitive than visible dye penetrants because of their lower viscosity and better see-ability.

- VISIBLE DYE – penetrants contain a colored dye which is usually red and is visible in white light. This penetrant is the least sensitive because visible dye penetrants have a higher viscosity.

- DUAL SENSITIVITY – penetrants contain a combination of orange visible dyes and yellow fluorescent dyes. The test article is viewed under black light when increased sensitivity is required.

- METHOD OF EXCESS PENETRANT REMOVAL from the test surface :

Penetrants can be further categorized by one of the three methods used to remove the excess penetrant from the test specimen surface.

- WATER-WASHABLE – penetrants contain a built-in emulsifier and are self-emulsifying. They are removable with plain water in a one step rinse process. The Water-Washable method is the least sensitive.

- POST-EMULSIFIED – penetrants require an emulsifier to be added in a separate step to make the penetrant removable with a water rinse. This is a two step removal process.

- SOLVENT-REMOVABLE – penetrants must be removed with a solvent. This is the most sensitive method.

Penetrant Removers

There are two basic types of removers and cleaners used to remove the excess penetrant from the test surface. The manufacturer designates the cleaner or remover that will be the best to use with a particular PT system.

- Solvent Cleaners and Removers

- Halogenated.

- Non-halogenated.

- Special Application

- Emulsifiers

- Lipophilic.

- Hydrophilic

Developers

Developers come in two basic forms, Wet and Dry. Depending on the manufacturer, developers can be substituted to enhance a PT system sensitivity.

- Dry Powder

- Non-aqueous Wet.

- Aqueous Wet

- Water Soluble

- Water Suspendable

-

NON DESTRUCTIVE TESTING

CLASSIFICATION OF LIQUID PENETRANT – METHODS AND TYPES

METHOD A – FLUORESCENT PENETRANTS

Type 1 (Procedure A-1) Water Washable Penetrant, Dry, Aqueous, or Non-aqueous

Developer.

Type 2 (Procedure A-2) Post emulsifiable Penetrant, Lipophilic or Hydrophilic

Emulsifier, Dry, Aqueous, or Non-aqueous Developer.

Type 3 (Procedure A-3) Solvent Removable Penetrant, Solvent Remover / Cleaner,

Non-aqueous Developer.

METHOD B – VISIBLE PENETRANTS

Type 1 (Procedure B-1) Water Washable Penetrant, Dry, Aqueous, or Non-aqueous

Developer.

Type 2 (Procedure B-2) Post emulsifiable Penetrant, Lipophilic or Hydrophilic Emulsifier,

Dry, Aqueous, or Non-aqueous Developer.

Type 3 (Procedure B-3) Solvent Removable Penetrant, Solvent Remover / Cleaner,

Non-aqueous Developer.

PROCESS SELECTION

The Selection of the best process depends upon:

- Sensitivity required or the smallest defect to be detected.

- Number of articles to be tested.

- Surface condition of the part being inspected.

- Configuration of the test specimen.

- Availability of water, electricity, compressed air and equipment.

- Suitability of the environment where the test will be performed.

- History of the test specimen:

- Manufacturing

- Overhaul or Repair

- In-Service

- Record of prior failures

- Governing Specifications and Codes.

Penetrant testing is successfully performed on Metals such as Aluminum, Magnesium, Brass, Copper, Carbon Steel, Stainless Steel, Titanium and most common alloys. It can also be used to test other materials including Glass, Ceramics, Composites, as well as some Plastics and molded Rubber products. Liquid penetrant testing is limited by its inability to detect discontinuities which are not open to the surface. Test surfaces must be clean and free of coatings and contaminants. The discontinuity must be open to the surface.

SPECIAL APPLICATION PENETRANTS

General

Penetrant materials are now biodegradable and safer for the environment. More recently, Dual sensitivity penetrants have given us the added capability of a fluorescent and visible dye mode in a single operation. Today, penetrants also come in gel, crayon, and magic marker forms for testing individual defects. They fit in your pocket.

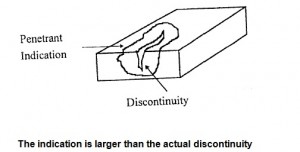

Filtered Particle Penetrant

Extremely porous surfaces, particularly ceramics and components which have been metal sprayed, can be tested with Filtered Particle penetrants. These penetrants are available in fluorescent filtered particles only. The particles are large and suspended in a liquid penetrant. The properly sized and shaped particles are larger than the opening of the discontinuity which is to be detected. The particles will accumulate at the top of the discontinuity forming an indication.

Liquid Oxygen Penetrants

Special organic penetrants are available for the testing of liquid oxygen components. Liquid oxygen has an average temperature of -275°F below zero and will instantly burst into flames when contact is made with a petroleum based product. Therefore, penetrant materials used to test LOX components must not have a petroleum base. Penetrants designed for this purpose can be used with dry powder and aqueous developers.

High and Low Temperature Penetrants

Liquid penetrant materials have made significant advances in physical characteristics which allow testing to be performed in extreme temperatures, above and below the normal operating temperature range of 60°-125°F ( 16°-52°C ). Viscosity’s of the penetrants have been modified to the point where they are extremely efficient. High viscosity penetrants are available for the testing of hot welds. Low viscosity penetrants are available for testing in extremely cold environments.

EQUIPMENT,LIGHTING, PENETRANT MATERIALS, CLASSIFICATION CODES, AND SAFETY

Penetrant Equipment

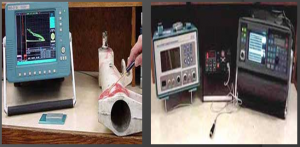

There are two types of penetrant equipment; Stationary and Portable. Stationary equipment is found in shops and permanent buildings and is primarily used for testing large components and large quantities of test articles. The equipment is not mobile because of the usage of large dip tanks, wash stations, oven dryers, and developer chambers. The equipment may be arranged in any order to fit the process application.

Portable equipment is primarily used in the field for on site testing. Field portable equipment could consist of portable electrical generators, black lights, pump spray bottles, air compressors, and penetrant kits. Solvent-Removable Penetrant kits contain the necessary materials for testing and were designed specifically to be portable in the field. Solvent Removable PT materials come in aerosol spray cans which also makes them difficult to contaminate.

Water-Washable penetrants are mostly used with stationary equipment but can be used in the field in portable, pressurized, pump bottle dispensers. Three pump bottles are used. One bottle is for the penetrant spray application and one for the rinse water. A third pump bottle may be required for developer application. Portable air compressors can be used to apply the penetrant materials with pressurized air.

Post-Emulsified Penetrant systems are not considered portable because they require an extensive pressurized rinse water supply and the materials are more susceptible to contamination. The Post-Emulsified penetrant process also utilizes more steps in the test process. It is not economical and is more time consuming.

Penetrant equipment also consists of a variety of test panels, light meters, thermometers, and gages necessary to monitor the system performance and the testing process.

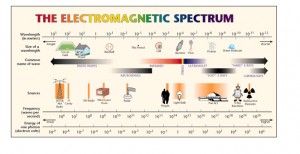

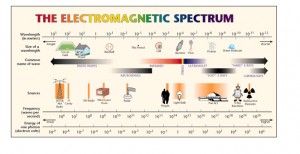

BLACK LIGHT

Black light equipment is required when performing fluorescent penetrant inspections. Black light is defined as electromagnetic radiation in the near ultraviolet wavelength range. UV light wavelength is measured in Angstroms ( A ) or Nanometers ( nm ) with 10 Angstroms equaling I Nanometer. The required wavelength of ultraviolet light is 365 nm or 3650 A. It is at this wavelength that the fluorescent dye in the liquid penetrant is activated. The dye absorbs the UV light, is energized, and emits a green fluorescent light at approximately 525 nm which is highly visible to the inspector.

A portable black light may be used with stationary or portable equipment. The black light equipment usually consists of a current regulating transformer, a mercury vapour arc bulb, and a deep purple, long wave, glass ultraviolet filter. The bulb and filter are contained in a reflector lamp unit and transformer and all electrical equipment is located inside the base of bulb.

Black light intensity is measured in microwatts per centimeter squared ( µW/cm2 ). For correct test results, the lamp must produce a minimum intensity of 1000 µW/cm2 for darkened areas or 3000 µW/cm2 for field inspections. It should be noted that black light intensity decreases as the light is moved further away from the test surface. Therefore, a specified distance is required to standardize the measurement. The standard measuring distance is 15 inches ( 38.1 cm ) from the front surface of the filter to the test object surface.

NON DESTRUCTIVE TESTING

NON DESTRUCTIVE TESTING

Bulbs and Filters

The deep purple filter on the black light is designed to pass only those wavelengths of light at 365 nanometers ( nm ) or 3650 Angstroms ( A ) which will energize the fluorescent dye in the penetrant. Longer wavelengths of the remaining visible light spectrum are filtered out. There are two kinds of filters, smooth and fluted. The smooth filter does not distort the light rays and allows them to pass without changing their path. The fluted filter diffracts the light rays scattering them over a wide area.

There are two types of mercury arc vapor bulbs used in black light equipment, the Spot bulb and the Flood bulb. The Spot bulb concentrates the rays of the light beam on a small area. The Flood bulb disperses the light rays over a wide area. If the Spot and Flood bulbs are rated at the same wattage or strength, the Spot bulb will read a higher intensity when measured because more light rays are concentrated in a smaller area. Both types of bulbs have an overheat switch located in the base of the bulb. The bulb will automatically shut down at a set temperature.

The intended usage of the black light unit and the intensities required for the inspection will dictate the best combination of bulb and filter. Fluted filters used in combination with Flood bulbs were designed for use during penetrant removal and are usually found in the rinse stations of PT stationary equipment. Spot bulbs coupled with Fluted filters are ideal for scanning large parts and large areas for indications. A Spot bulb used with a Smooth filter is best for the inspection of small areas or small components. This combination is best because it gives the maximum intensity on the test surface in the area of interest.

Measurement

Black light can be measured with a Spectroline DM-365X digital readout meter, UVP Black Ray J-221 mechanical gage meter, Spectroline DSE-100X digital readout, combination white and black light meter or an authorized equivalent. The light should be pointed in line with and centered over the light sensor at a distance of 15 inches ( 38.1 cm ) between the sensor and the light. The light can be moved back and forth or side to side until the highest reading is obtained. Black light intensity levels should be recorded on the PT Inspection Report and the Ultraviolet Light Intensity Log Sheet as required. A Light Intensity Log should be kept with the black light at all times.

The ultraviolet light intensity at the examination surface shall be measured:

- At least every 4 hours.

- Whenever the work location is changed.

- After changing a component of the unit such as a filter or bulb.

- After a UV light unit failure.

Equipment Operation

The full intensity of the lamp is not attained until the mercury vapor arc bulb is sufficiently heated. At least a 5 minutes warm-up time is required for the bulb to reach the required arc temperature. Should the bulb go out for any reason, intentionally or accidentally, the unit will not restart if it is immediately turned back on. You must always allow a 10 to 20 minutes cool down period before a restart is attempted.

Once turned on, the lamp should be left on during the entire working period. Frequently switching the light on and off, for whatever reason, shortens the life of the bulb significantly. Material is removed from the bulb electrode at each start. A single start is the equivalent of several hours of burning time. A stable electrical source should also be used. Line voltage drops will cause the lamp to extinguish or go out, requiring a restart. Line voltage increases will drastically reduce bulb life.

Mercury vapor arc black light bulbs fade proportionally with operation time. Black light intensity can fade more than 50% before the bulb burns out. Light intensity measurements should be recorded every 4 hours on an Ultraviolet Light Intensity Log sheet. The log sheet should be reviewed periodically to track the bulb intensity for fading trends. A dirty, heavily scratched, or cracked filter can reduce black light intensity. Filters should be cleaned on the inside and the outside and checked before each use. Cracked or excessively scratched filters should be replaced immediately. Cracked lenses expose white light emitted by the mercury vapor arc bulb and are dangerous to the inspector. NEVER look directly into an operating mercury vapor arc bulb without a filter.

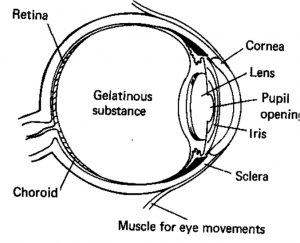

Eye Adaptation

A minimum of 5 minutes should be waited after entering a darkened area and before inspection begins. This is called an eye adaptation period and will allow the pupils of the eye to expand and adjust to the darkened condition. A short period for eye reorientation should also be allowed after looking directly into an operating black light. Although it is not harmful, this may cause the eyes to become cloudy due to the cornea of the eye fluorescing. Do not wear glasses with photo-chromatic or light sensitive lenses while performing any PT inspections. UV light will tend to darken the lenses.

Darkened Area Inspection

To achieve maximum black light intensity, fluorescent penetrant inspections should be performed in a darkened area. A maximum white light intensity of 2 ft-candles or 22 lux ( lx ) is allowable in a darkened area or booth. All attempts should be made to darken the area where a fluorescent penetrant inspection will take place in the field. Even if you can not darken the area to 2 ftc ( 22 lx ) or below, darken the area as much as possible. This can be done utilizing a black blanket, hood, or a portable enclosed booth. White light penetrating the darkened booth, in sufficient quantity, absorbs the filtered ultraviolet light. This reduces the intensity of the ultraviolet light, the see-ability of any indications, and the sensitivity of the inspection. It is for this reason that every attempt should be made to darken the test area as much as possible. White light should be measured before each fluorescent penetrant inspection, whether performed in the field or in a darkened area. A white light measurement is taken before performing a fluorescent penetrant examination to determine the minimum black light intensity requirements.

Black Light Usage

The black light will always be used four times during a fluorescent penetrant inspection. The inspector will verify that the Pre-cleaning (Step 1) and Post-cleaning (Step 6) operations have been thorough and complete by scanning the test surface with the black light. Excess Penetrant Removal (Step 3) and the Interpretation and Evaluation (Step 5) of indications will also be performed with the test surface illuminated with black light.

TROUBLESHOOTING AND REVIEW

A bulb and lens filter combination used for a penetrant test must insure the minimum required light intensity is projected on the test surface. The rule of thumb is the highest intensity possible is the most desirable.

Light intensity to be checked every 4 hours, when changing job sites, after a black light unit failure, or after changing a bulb or filter. Minimum intensity should be:

- 1000 µm/cm2 @ 15 inches (38.1 cm) for darkened areas 2 ftc(22 lux) or less of white light.

- 3000 µw/cm2 @ 15 inches (38.1 cm) for field inspections or areas of white light greater than 2 ftc (22 lux).

Causes for black Light failure:

- a) Power disconnected.

- b) Line voltage fluctuation.

- Low Voltage – Will cause Bulb to turn off.

- High Voltage – Will cause bulb to burn out.

- c) Overheat – Thermal switch cutout or fan inoperative.

- d) Bulb burned out

Causes for low intensity output:

- a) Dirty, excessively scratched or cracked lens

- b) Bulb fading

- c) Excessive ambient white light.

- d) Light meter out of calibration.

Procedure to check operation or bulb integrity after a failure:

- a) Turn off unit and allow 15 minutes for unit to cool down.

- b) Check power to the unit, turn the unit on and allow 5 minutes for bulb warm up.

- c) Measure light intensity and check fan operation if so equipped.

- d) Replace bulb if inoperative or intensity is below minimum requirements.

- e) If bulb is still inoperative, replace unit.

WHITE LIGHT

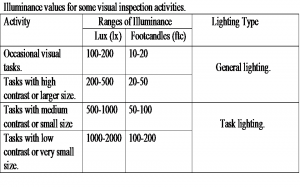

Requirements

The amount of visible white light necessary to perform a visible dye penetrant inspection is measured in Lux (Lx) or Foot-Candles (ftc). 11. White light intensity of 32.5 ftc (355 Lux) at the examination surface for a field inspection and 100 ftc (1076 Lux) minimum for a bench examination.

White light is necessary throughout the inspection process but is very important during Interpretation and Evaluation (Step 5). Elevated white light intensities greatly increase the contrast of the red penetrant indications against the white developer background. This makes the indications easier to see and reduces eye strain and eye fatigue.

Measurement

White light can be measured using a digital light meter, or an authorized equivalent. When measuring light intensity, the light sensor or meter should be placed on the surface to be inspected in a configuration reproducing the normal viewing of the test specimen by the inspector. White light levels should be measured before each inspection and recorded on the inspection report.

PENETRANT TESTING MATERIALS

Penetrant materials are often restricted to specific groups. The established groups can use a combination of penetrant materials to obtain the best results.

- WATER-WASHABLE PENETRANTS – contain an emulsifying agent which makes them easily removable in one (1) step with a water rinse or wash. They were specifically designed for ease of removal from rough surfaces such as castings, for testing large parts, large quantities of parts, and parts with complicated shapes. Penetrant removal is extremely critical because the penetrant is easily over-washed. This type of penetrant can be obtained in either a fluorescent or visible. dye.

- POST-EMULSIFIABLE ( PE ) PENETRANTS – are high sensitivity, oil based, visible, or fluorescent penetrants that are not soluble in water. These penetrants must be treated with an emulsifier before they can be removed by a water rinse. The emulsifier is added separately to make the penetrant water soluble and then rinsed off. This procedure is referred to as a two (2) step removal process. PE penetrants are not as easily over-washed as Water-Washable penetrants. They are mostly used in stationary equipment and are not considered portable.

- SOLVENT-REMOVABLE PENETRANTS – are oil based penetrants that also do not contain an emulsifying agent. They are identical to PE penetrants except they are manually removed by wiping the test surface with a solvent dampened cloth or rag. These penetrants are specifically designed to be portable and come in pressurized spray cans. They are available in visible or fluorescent types.

- EMULSIFIERS – are applied to a penetrant coated surface and makes the resultant mixture removable by a water rinse or wash. Emulsifiers have low penetrating characteristics so they will not remove indications from the test specimen surface. There are two (2) kinds of emulsifiers. Lipophilic emulsifiers quickly diffuse into the penetrant on the test surface in 1 to 4 minutes much like a solvent. Hydrophilic emulsifiers react more slowly. They are commonly sprayed on the test surface in a water mixture. The excess penetrant is removed with the assistance of a scrubbing action water spray like a detergent. Emulsifiers only come in bulk containers and are not portable.

- SOLVENT REMOVERS – are designed to be used with specific penetrants. Typical removers are organic or man-made petroleum based chemicals. They come in bulk containers for use in spray guns or portable aerosol spray containers. They are typically used 3 times during a penetrant test for pre-cleaning, excess penetrant removal, and post-cleaning.

- DRY DEVELOPERS – are a fluffy, absorbent, white powder that is used in both fluorescent and visible dye penetrant tests. These developers are not mixed with anything and applied in a dry state by dusting. They are only available in bulk and are primarily used with stationary equipment such as dust chambers. They can also be applied manually with a squeeze bulb. Dry developers are very sensitive. They are excellent for use on parts with rough surfaces and

complicated geometries and are easily removed. Dry powder developers are rarely used in the field and not considered portable.

- AQUEOUS WET DEVELOPERS – are a mixture of water and white developing powder. Water is used as the delivery vehicle to apply the developer to the test surface. Application is by dipping or spraying. There are two (2) kinds of Aqueous Wet developers. Water Soluble is a mixture of water and powder where the powder dissolves in the water. Water Suspendable

developer keeps the powder particles suspended in the water. The particles do not dissolve in the water. Water Suspendable developer is considered the least sensitive of all the developers. Aqueous developers are best used on parts with smooth surfaces and simple shapes.

- NON-AOUEOUS WET DEVELOPERS – differ from wet developers because, the powder particles are mixed with a quick drying solvent. The powder is suspended in the solvent and is applied to the test surface by spraying. These developers are most commonly used in aerosol spray cans which makes them portable. They can not be used in open tanks because the solvent base evaporates too quickly. The use of solvent as a delivery vehicle is what makes Non-aqueous wet developers the most sensitive for the detection of extremely small and tight defects.

- LIQUID OXYGEN ( LOX ) COMPATIBLE MATERIALS – must be used when testing parts that will be in contact with either liquid or gaseous oxygen. These materials are specifically designed to be inert when in the presence of LOX.

- FILTERED PARTICLE PENETRANTS – are used for testing porous surfaces, such as unfired ceramics and thermal sprayed metal and coatings. They use large fluorescent particles which gather at the top of a discontinuity to form an indication rather than penetrate the into the discontinuity cavity.

Corrosive Contents

Penetrant materials must be designed with a low sulfur and halogen content to avoid harmful effects on the test articles. These chemicals will promote corrosion and in some cases hydrogen Embrittlement. Stainless Steels are especially susceptible to corrosion when exposed to Chlorine and Carbon Steels to Sulfur. Titanium is extremely susceptible to Embrittlement when in contact with Halogens. These harmful chemicals can be found in small amounts in all the penetrant materials and are limited to 1% by weight of content.

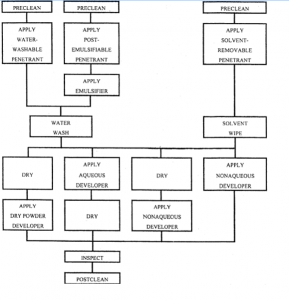

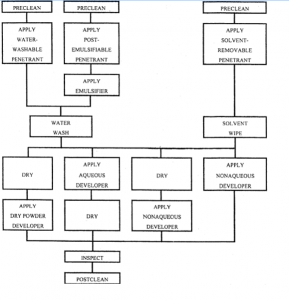

Penetrant materials can be used in a variety of combinations. Most materials are available in either bulk quantities or pressurized spray cans. All penetrants are available in either visible or fluorescent types. The flow chart below illustrates the different material combinations. However, it can not be overstated that care should always be taken to assure that the manufacturers specifications and company procedures are closely followed. The manufacturer designed the material groups and designates the groups and combinations that will give the best test results. It is the responsibility of the Saudi Aramco NDT Level III to authorize a compatible material group for use or a suitable substitute material if required.

LIQUID PENETRANT MATERIAL FAMILIES

Penetrant Material Selection

A family or group of penetrant materials will always include a penetrant, cleaner or remover, and developer. The manufacturer designates the compatible family and group. Substituting products from the same manufacturer is not allowed unless the manufacturer recommends it. These are penetrant materials that are designed to work well together and will when selecting your consumables before a PT , NEVER substitute penetrant materials made by different manufacturers in a family. NEVER substitute penetrant materials from different groups either. This is especially true when using fluorescent penetrant materials. Certain chemicals may degrade the brightness of the penetrant indication. A penetrant test procedure using substitute materials from different manufacturers is not valid unless qualified by a certified NDT Level III.

Part Numbers & Batch Numbers

Some material part numbers may have different letters or numbers at the end of the part number. This indicates a revision has taken place. The manufacturer may have changed an ingredient in the material or possibly the propellant in the spray can. It should be confirmed that the product is still compatible with the family. Batch numbers are supplied by the manufacturer to provide traceability from the manufacturer to the inspection test and usually indicate the date the material was manufactured. Batch numbers are usually found somewhere on the material containers stamped in ink. If they are not stamped on the containers or aerosol cans, they may be found on the box the cans were shipped in or the certificate of compliance ( C of C ) received with the shipment. The penetrant batch number will be recorded on the inspection report along with the part numbers of all the penetrant materials used for the test.

Batch Numbers

Batch numbers are supplied by the manufacturer to provide traceability from the manufacturer to the inspection test and usually indicate the date the material was manufactured. Batch numbers are usually found somewhere on the material containers stamped in ink. If they are not stamped on the containers or aerosol cans, they may be found on the box the cans were shipped in or the certificate of compliance (C of C) received with the shipment. The penetrant batch number will be recorded on the inspection report along with the part numbers of all the penetrant.

LIQUID PENETRANT MATERIAL FAMILIES

A-1 Fluorescent Water Washable (Group IV)

| SHERWIN |

HM-420, HM-430,

HM-604 |

Water |

D-90G, D-100, D-100NF |

| ARDROX |

P133D or P134D |

Water |

9D1B, 9D4A, 9D6/D495A,

D499C |

| MAGNAFLUX |

ZL-56 or ZL-67 |

Water |

ZP-4B or ZP-9F |

B-I Visible Dye Water Washable (Group III)

| SHERWIN |

DP-50 or DP-51 |

DR-60 or Water |

D-90G, D-100, D-100NF |

| ARDROX |

996/P303A |

Water |

9D1B, 9D4A, 9D6/D495A,

D499C |

| MAGNAFLUX |

SKL-WP |

SKC-S or Water |

ZP-4B, SKD-NF, SKD-S2 |

A-3 Fluorescent Solvent Removable (Group VII)

| SHERWIN |

RC-65 or RC-77 |

DR-60 or DR-61 |

D- 100 or D-100NF |

| MAGNAFLUX |

ZL-27A |

SKC-NF/ZC-7 or SKC-S |

SKD-NF/ZP-9 or ZP-9F |

| ARDROX |

996/P300A |

9PR50, 9PR551, K410C,

PR1 |

9DIB, 9D6/D495A,

D499C |

| CROWN |

1032 |

1031 |

1033 |

B-3 Visible Dye Solvent Removable (Group I)

| TURCO |

Dy-Chek |

Remover #3 |

NAD |

| CROWN |

1075 |

1071 |

1079 |

| MAGNAFLUX |

SKL-LO or SKL-SP |

SKC-NF/ZC-7 or SKC-S |

SKD-NF/ZP-9 or SKD-S2 |

| SHERWIN |

DP-40 |

DR-60 or DR-61 |

D-100 or D-100NF |

| ARDROX |

996/P300A |

9PR50, 9PR551, K41OC,

PRl |

9D1B, 9D6/D495A,

D499C |

| CASTROL |

222 |

S – 72 |

LD-3 |

| JOHNSON and ALLEN |

JAP |

JAC or JAC II |

JAD |

SAFETY

Liquid Penetrant Materials and Usage

The materials used in Liquid Penetrant testing can be harmful to the test operator or the component under test. Generally speaking, it is a relatively safe method of testing unless it is abused or certain simple precautions are not taken. Although flash points of penetrants and emulsifiers average above 200°F, they are still considered flammable, especially when used in open dip tanks. Liquid Penetrant materials should NEVER be used near open flames, electrical arcing such as welding, or exposed to extremely high heat sources above their operating temperature range.

Vapors from the penetrants and emulsifiers are basically harmless to the test operator. Prolonged skin contact can cause skin rashes and should be avoided. Rubber gloves and a rubber protective apron should be worn when possible. Safety glasses should ALWAYS be worn to avoid eye contact safety shoes with steel toe tips should be standard attire. Handling parts coated with penetrants are slippery and can be easily dropped.

Solvents can be dangerous because of their high volatility, low flash points, high flammability, and toxic vapors. ALWAYS use in a well ventilated area with good air circulation. Breathing the vapors can cause dizziness. Enclosed areas will require filtered breathing apparatus such as a respirator to be worn. The solvents should NEVER be used near open flames or potential electrical arcing.

Non-aqueous developers also contain the same solvents used for cleaning and penetrant removal, in addition to developer powder. The same precautions should be observed as when using the solvents for cleaning. Although developer powders are considered nontoxic, excessive inhalation should also be avoided.

Storage and Handling

Care should be exercised during storage, handling, and transporting of penetrant materials. Storage should be in dry areas, preferably at room temperatures. Exposure of materials to direct sunlight and extreme temperatures outside of their normal operating range, even in sealed containers, can cause contents to separate permanently or degrade their sensitivity. Fluorescent penetrants are susceptible to dye separation and fading. Non-aqueous developers tend to coagulate and get lumpy in the aerosol can. Solvent removable penetrant materials in aerosol cans are susceptible to exploding in temperatures above 120°F ( 50°C ), regardless of their flash point. The propellants in the aerosol cans expand proportionally with increases in heat.

Testing Precautions

Any of these materials may be harmful to the test article if plastics or rubbers are involved. If possible, a sample test article should be inspected first to determine if the penetrant materials will damage the test article. Some rubbers expand when in prolonged contact with penetrants and some plastics may melt or become permanently stained. Performing Liquid Penetrant testing on assembled parts with gaskets should be avoided. If possible, the component should be disassembled and done in individual pieces. This also provides accessibility to flange mating surfaces.

Equipment

Black light ultraviolet emissions are harmless to the skin and eyes provided the equipment is maintained. The black light will not cause sunburn and is not harmful if shined in your eyes as long as the proper filter is in place. However, light emission from an unfiltered mercury vapor arc bulb is extremely harmful to the human eye and will cause sunburn.

SURFACE PREPARATION

Surface Cleaning

Pre-cleaning is the very first step when performing a liquid penetrant inspection. The effectiveness of a penetrant test is based upon the ability of the penetrant to enter surface discontinuities. Contaminants including grease, carbon, dirt, scale, varnish, oil, oxides, corrosion and water must be removed from the test surface and the discontinuity cavity. All paint, plating, core material is the most common contaminant, the test surface should also be thoroughly dry before the penetrant is applied to the surface.

Liquid penetrant placed on the surface of a test specimen does not only seep into a flaw cavity, it is pulled into them by capillary action. Proper cleaning is essential to liquid penetrant testing for three reasons :

Contaminant will prevent the penetrant from wetting the surface properly and block the entrance of penetrant into the flaw cavity. Discontinuities must be open to the surface.

If all traces of penetrant materials are not removed after the test, they may have a harmful effect on the test specimen. Sulfur and halogens will promote corrosion and in some cases hydrogen Embrittlement in some alloys.

Acids, water and salts can affect the sensitivity of the penetrant. This is specially true for fluorescent penetrants.

A visual inspection will always be accomplished before, during and after the pre-cleaning procedure. The purpose is to select the proper pre-cleaning method, assure that the test surface is contaminant free, identify gross discontinuities and identify any areas of interest where an indication will be expected to occur. A contaminant is defined as any foreign material on the surface that will prevent the penetrant materials from performing their intended functions. An area of interest is defined as any irregularity on the surface where a penetrant indication will be expected to form.

There are several contaminant removal methods to choose from. The selection of the proper method depends on the type of the contaminant you wish to remove and the type of material you wish to remove it from. The ideal method selected will remove the contaminants and not disturb or damage the surface of the material to be tested.

- DETERGENT SOLUTIONS : are a common means of pre-cleaning to remove contaminants and residual chemical films from the component surface. Initial pre-cleaning is for removal of dirt and soil. Some industrial detergents will also remove oil and grease. Secondary pre-cleaning is for removal of residual chemicals or oily films after paint stripping, acid or alkaline cleaning or an etching procedure has been accomplished. Detergent cleaning is accomplished by scrubbing with a soft bristle brush, rinsing and drying.

- STEAM CLEANING : is performed with a heated degreasing or detergent solution applied in a high pressure spray. It is particularly adaptable to the cleaning of large or bulky articles which can not be handled easily.

- SOLVENT CLEANING : may be applied by flushing the test surface with spray, a wipe on and off technique or immersed in a dip tank. It is the most commonly used method for pre-cleaning and must be performed in a well ventilated area due to the toxicity of the vapors.

- ACID & ALKALINE CLEANERS : are used for corrosion, rust and scale removal. They are usually applied by dipping or brushing and allowed to dwell on the surface for a certain period of time and rinsed off. The manufacturers instructions should be closely adhered to or this method could damage the part. An acid or alkaline cleaning is always followed by a detergent washing or solvent flushing to assure the test surface is totally free of residual chemicals.

- VAPOR DEGREASING : is the most desirable method for removal of oil, grease and similar contaminants. However, certain alloys such as titanium have an affinity for specific elements used in vapor degreasing which may cause structural damage. Vapor degreasing is performed by dipping the part in a tank of degreasing vapor and usually accompanied by heat. When allowed to soak in the vapor for a sufficient time, the vapor will penetrate into the discontinuity openings. This makes vapor degreasing a very through cleaning method.

(In Next Article We Discuss the Remaining Topics of Non Destructive Testing ( Liquid Penetrant Testing)….)